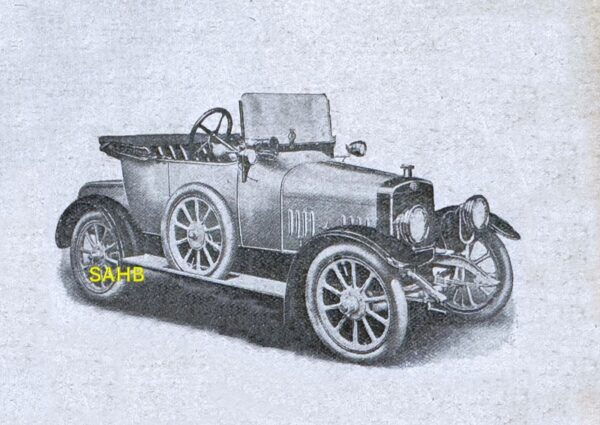

At first glance this small car is just like so many others seen after World War I, often with many bought-in parts and manufactured in modest workshops by enthusiasts driven more by hope than experience. But this Day-Leeds does stand out from the crowd.

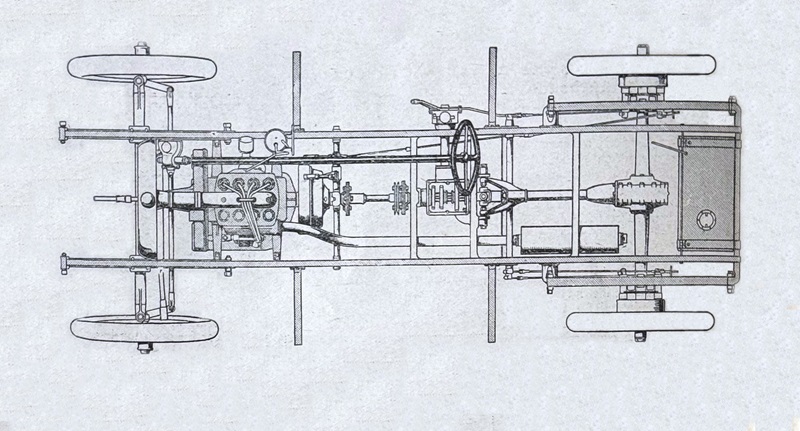

Instead of being a bought-in side-valve four-cylinder, the power unit of this car was manufactured by the company itself – and to a relatively unusual design for this class of small car: a T-head, with a camshaft on each side of the block driving two rows of side-valves, to give a cross-flow configuration.

In 1901 William Henry Day, a chartered accountant who had set up as a chemist in 1886, founded Job Day & Sons in Leeds. The name was that of his father, Job Day, a Lincolnshire framer who played no part in the company. William was in partnership with his brothers Albert and Charles; they manufactured engines designed by William and packaging machinery designed by Albert – so the seeds were sown for a car manufacturer perhaps a little more distinguished than the common herd.

Their first car was introduced in 1912; it was a cyclecar powered by a 998cc V-twin engine built by themselves. Motorcycles were also offered, with a single-cylinder 499cc engine – no doubt using the same cylinder as one half of their twin.

A more ambitious and fully conventional light car was shown at the 1913 London Motor Show with a 1,130cc four-cylinder engine by Turner, but the engine was replaced soon after by the 1,286cc water-cooled T-head engine that we have referred to earlier. It was designed by W L Adams of the Laxtonia Engine Works of Peterborough; he also designed an aero engine in World War I. This model was revived after the war, now with electric lighting to replace acetylene. Acetylene. The local company Lockwood and Clarkson of Barclay Street in Leeds built the two-seater open body that we see in the Snapshot.

The press review in November 1919 praised the roomy and rattle-free body, and had good words to say about the engine, explaining that the T-head design allowed large 40mm-diameter valves that rendered the engine “efficient and adaptable for high speeds.” Since a picture is always worth a thousand words, we reproduce here the plan view of the car that shows the eight removable caps that gave access to the valves, four of them doubling as holders for the four spark plugs.

Sadly, the price quoted was an uncompetitive £400, and this was progressively reduced to £225 by end of production in 1926. Only around 300 post-war cars were produced, and two are thought to have survived.

The company did continue to make packaging machinery and was eventually absorbed into Baker Perkins.

Image courtesy of The Richard Roberts Archive: www.richardrobertsarchive.org.uk

Leave a Comment