County Commercial Cars Limited of Fleet in Hampshire were known for their conversion of Ford lorries. They were also the patent holders for the JEKTA telescoping discharge system for municipal vehicles and tippers. In 1948, Walker Brothers of Wigan, Lancashire, went into collaboration with County to form a new company called Walkers & County Cars Limited, to manufacture bodies with the JEKTA system.

Much was claimed of the system in a brochure published by Walkers & County Cars. Starting with the simple statement “It works like a Telescope” the promotional copy went on to explain, with copious use of italics and exclamation marks for emphasis:

“While a tipping body is lifted at one end to enable its contents to fall, the JEKTA remains horizontal and forcibly ejects its load.

“It follows that while the JEKTA can do anything of which a tipper is capable, it has several features which a tipper cannot emulate:

- Some materials will not fall. They have to be pushed. There is no “chassis buckling” with the JEKTA. That is good news for the repair shop!

- The user does not always want a full load dumped at one spot. The JEKTA discharge is controlled. The whole or any part of a load can be pushed off at will. This saves double handling. Man-hours!

- There are many places where headroom restricts the overall height of a vehicle. This JEKTA dimension never varies. Wherever the vehicle can go, it can discharge. The JEKTA can get there!”

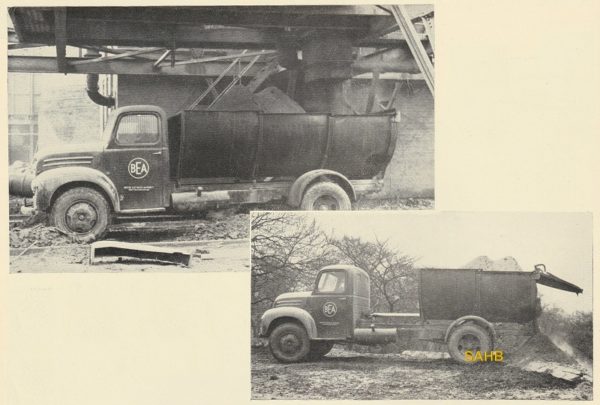

Our Snapshot double image is taken directly from the brochure. It shows a Ford Thames ET with the JEKTA system, operating at the Agecroft Power Station of the British Electricity Authority to eject fly ash produced from the burning of pulverised fuel – reportedly “hardly dischargeable from a tipping body”. It shows how the front section of the U-shaped three-part body telescopes into the rear sections. But the most important element is unseen: a sloped ramp in the front section. A hydraulic ram pushed this front section into the second section, which in turn pushed into the rear, fixed, section. The lower edge of the sloped ramp thus ended up flush with the rear of the final fixed section when fully pushed rearwards – so all material would be ejected. Curiously, no known promotional pictures exist of the three sections telescoped together – perhaps because the lorry would then look rear-heavy, even though only some material from the sloping front section would be hanging over the back axle. However, a search in the Commercial Motor digital archive revealed that all the sections do in fact telescope together.

Walkers & County Cars offered an ambitious range of JEKTA bodies, from three-section bodies of 4 cubic yards capacity to five-section bodies on 6- or 8-wheeler chassis with a capacity of 40 cubic yards (using wire ropes to multiply the movement of the hydraulic ram). Sadly, however, little now remains of this apparently highly effective idea, apart from one grainy photograph on the internet of the largest version, named Super JEKTA.

Photo courtesy of The Richard Roberts Archive: www.richardrobertsarchive.org.uk

Leave a Comment