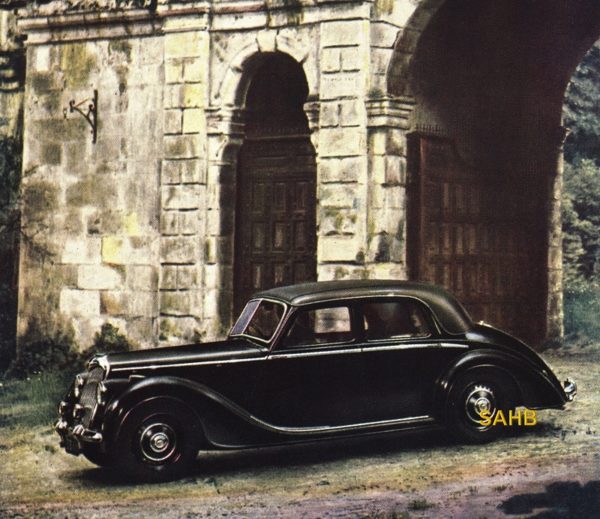

The post-war Riley feels as if it has deserved a Snapshot for many years – but it also deserved a colour picture. In this case the image is from the original publicity for the car in November 1945.

This model is now known as the first of the famous RM series. It was the last model developed by Riley before their owners from 1938, Nuffield, merged in 1952 with Austin to form BMC. That RM designation was invented by BMC: just as they used the MO code for Morris, they used RM to denote Riley Motors.

Nuffield had acquired Riley in 1938 and had set about a drastic pruning of the Riley range. Only the 1½ litre Riley 12 and the Big 4 Riley 16 (later the 2½ litre) were continued in production. They had synchromesh gearboxes and bodies similar to those of their Nuffield sisters from Wolseley.

The post-war successors, starting with the 1½ Litre in our Snapshot, had the same engines (1½ & 2½ litre) as the pre-war cars but gained new bodies with fabric roofs. Unlike those of many competitors, the bodies were not carried over from before the war – apparently for a specific reason: the patterns for the body dies had been destroyed in the air raids on Coventry. Nevertheless, the look of the new body was still highly traditional, with a definite pre-war look.

The construction of the car was equally traditional. The body frame was made of ash; it required labour-intensive techniques to produce and was a weak point that does not help the survival of the cars today. Bonnet tops were made from aluminium, but the rest of the panelwork was in steel. The complicated roof comprised perforated steel topped by hessian and Everflex rexine. This gave good insulation, but poor long-term protection of the frame. Less obviously, chassis manufacture was also time-consuming and costly: a photo of the chassis under construction at the Coventry works in 1948 showed a complex jig-building process with much manual labour involved.

A positive development from wartime experience was the fitting of torsion bar independent front suspension. The hydro-mechanical brakes were kept until 1952 when they were converted to full hydraulics. Although the cars were originally built in Coventry, in 1949 production moved to the MG factory at Abingdon. The engines were of classic Riley design: four cylinders in-line, hemispherical combustion chambers and twin camshafts mounted high at the sides of the cylinder block.

Despite the complexity and cost of the build process, the RM series cars were successful. 13,950 1½-litre saloons (RMA and the 1952 RME) were sold between 1945 and 1955, with 7,950 2½-litre saloons (RMB and RMF) from 1946 until 1953. Roadsters (RMC) between 1948 and 1950 and dropheads (RMD) from 1949 to 1951, both on the 2½-litre chassis, contributed a further 500 cars for each body. The replacement for the larger car was the RMH Pathfinder, with a new body but the traditional engine, said to be the last of the ‘real’ Rileys.

Photo courtesy of The Richard Roberts Archive.

Leave a Comment